Description

Pharmaceutical flooring: Epoxy flooring in the pharmaceutical industry must be of a type that can maintain healthy and hygienic conditions in the factory environment. One of the most important features of flooring suitable for pharmacies is its resistance to acids and alkalis. Also, having a smooth and non-slip surface to prevent pharmaceutical employees from falling and slipping is another important factor in the proper flooring of pharmacies. The best type of flooring for pharmacies and its features are presented on this page.

Pharmaceutical Epoxy Flooring

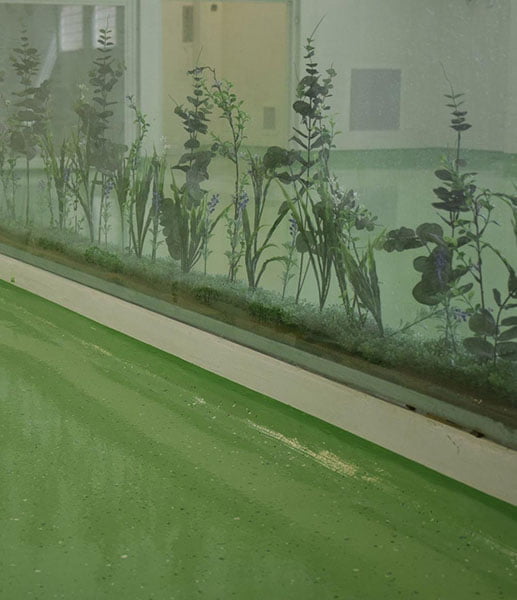

The flooring of various pharmaceutical departments, including clean room flooring, process lines, research and development laboratories, etc., not only requires high chemical resistance and anti-static properties but also must be sterile to a high degree. Corrosion resistance, waterproofness, antibacterial properties, and thermal and acoustic insulation are also other necessary features for medical flooring.

Pharmaceutical epoxy flooring is one of the most common and best types of flooring for different sectors. This type of flooring is ideal for environments that require hygiene due to its properties such as resistance to corrosion, water, and infection.

Epoxy flooring is usually produced in different colors and with different thicknesses. This type of flooring reduces the permeability of various liquids and chemicals, and as a result, it will prevent the possibility of spreading viruses and bacteria in the pharmaceutical environment.

Besapolymer sanitary and pharmaceutical flooring has no connection areas, as a result, cracks and crevices, which are places for dust accumulation, are removed from the system and ease of cleaning is created, as well as against the wide variety of chemicals used in the pharmaceutical industry. are placed, they are resistant and they work in a wide range of temperatures.

Advantages of Epoxy Flooring in the Pharmaceutical Industry:

In addition to epoxy flooring, various types of resin flooring (epoxy, polyurethane, and acrylate) can also be used for different pharmaceutical sectors. Among the advantages of these floors include:

• Integrated and seamless,

• Antistatic

• Anti-slip

• Sterile, dust-free, stain-proof

• Ease of cleaning and maintenance

• High chemical resistance

• Ensuring minimal disruption and minimal downtime for installation and implementation of high-drying speed flooring

• Stable and wear-resistant surface

It should be noted that according to the guidelines for the establishment, operation, and inspection of pharmaceutical factories published by the Food and Drug Organization, the use of resin flooring is mandatory in all production departments.

Read more:

Pharmaceutical Flooring Installation

Installing epoxy flooring for pharmacies requires expertise and technical knowledge and should be done by skilled experts. Also, after installing the epoxy floor, you should maintain it periodically to maintain its durability and long life.

Some pharmaceutical flooring projects implemented by Besapolymer material:

|

|

|

Gallery of Medicinal Sanitary Flooring Projects

The Floor of the Weighing Room of the Pharmaceutical Factory

Every pharmaceutical manufacturing plant has an area where raw materials are weighed and transferred to clean containers. This area includes various names, including weighing, weighing room, central weighing, pharmaceutical, distribution area, division (part by part), and department.

The weighing room consists of three parts:

1- Location of raw materials

2- Weighing room

3- The location of the weighing delivery process to production

In accordance with the instructions for the establishment, operation, and inspection of pharmaceutical factories of the Food and Drug Organization, the pharmaceutical flooring used in the weighing room in pharmaceutical factories should be designed and built as follows:

⦁ The flooring must be completely resistant and impervious, anti-acid (like epoxy flooring), smooth, and without voids, cracks, and grooves.

⦁ It can be washed and has a sufficient slope towards the sewerage, to prevent the accumulation of water on the floor of the production hall.

⦁ The angle between the flooring and the wall should be curved.

In a case study, the type of flooring and the installation and implementation steps of the resin flooring used in the weighing room of one of Tehran’s pharmaceuticals have been investigated:

Description of pharmaceutical requirements: According to the request of the technical management of the pharmaceutical industry, the weighing room needed a floor covering with high wear resistance and at the same time with a high speed of installation and execution of the flooring due to the high traffic of people and equipment, because of the importance of the weighing room in the drug production process. In this factory, it was not possible to stop the production line, and the installation operation had to be completed on weekends.

Specifications of pharmaceutical weighing hall flooring:

Size: 400 square meters

Derived from: Concrete

Required flooring considerations: high abrasion resistance/high installation speed of the flooring

Type of selected resin flooring: acrylate flooring or MMA flooring

The resin flooring system designed for this use was resin flooring based on methyl methacrylate resin (MMA flooring) due to its very high curing speed in addition to its suitable abrasion resistance.

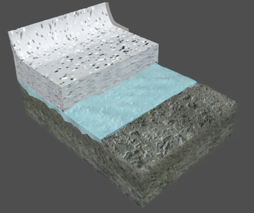

Due to the very high curing and polymerization speed, MMA flooring can be used only two hours after the completion of the flooring operation. The MMA flooring used in this weighing room consisted of three main layers: primer, intermediate (with Flake Design), and a protective coating.

also, Read:

Reviews

There are no reviews yet.