Sports venues need integrated, flexible, and quality flooring. Sports flooring must have the necessary resistance to impact force, friction, and scratches, as well as outdoor UV radiation.

Polyurethane sports flooring, integrated, seamless, and in different colors, can be applied with the necessary strength and high flexibility. The high flexibility of polyurethane flooring also minimizes the possibility of injury to athletes. This article fully presents the benefits of using polyurethane sports flooring, its installation, and its cost.

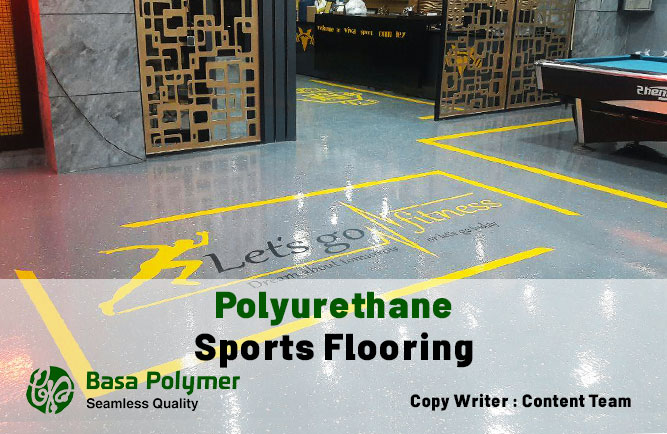

Polyurethane gym flooring

The gym’s atmosphere should be in addition to beauty, standards including antibacterial and fungal, easy washing, impact resistance, high flexibility and elasticity, the possibility of line drawing, suitable for sports activities for athletes, etc.

The thickness of polyurethane sports flooring can vary depending on applications and the intended cost.

Sports flooring should have certain specifications according to different uses and international standards. The thickness of the floor and technical specifications are under the requirements and standards of comfort and safety for athletes. The most important factors to consider in sports flooring are as follows:

- Safety

- Impact absorption

- Sports flooring surface friction

- Fireproofing

- Flat and smooth

- Impact resistance

- Rotational load resistance

- Factory quality control

These factors vary in different uses and mutually affect the thickness of the floor. Polyurethane flooring is the best choice for gyms and sports fields according to the mentioned factors.

However, in some applications, epoxy flooring can be used to reduce the cost of the sports flooring. Epoxy flooring is suitable both for hygiene and for line drawing. Although it does not have the flexibility and force absorption of polyurethane flooring, it still has higher safety than other floorings.

Another feature of this type of flooring is applying it on all kinds of surfaces (stone, metal, ceramic, mosaic, concrete, etc.).

Polyurethane sports flooring can be produced and executed with a glossy, attractive, and integrated surface in different designs and colors. It is also possible to draw lines on the flooring.

The antibacterial properties of polyurethane sports flooring also prevent the absorption of germs or bacteria.

Polyurethane flooring can be repaired, easy to install, and due to the optimal supply of raw materials, it reduces polymer waste and reduces the cost of execution.

Application of polyurethane sports flooring

- Indoor gyms

- Outdoor sports fields

- Children playgrounds

- Stadium floorings

- Sports clubs (bodybuilding, etc.)

- Bicycle tracks

- Track and Field stadiums

Installation of polyurethane sports flooring

Although the installation steps of polyurethane flooring are generally similar to epoxy flooring and other types of resin flooring, the method of polyurethane flooring is slightly different from epoxy flooring.

One of the most important differences of polyurethane flooring is its very high sensitivity to moisture in the environment. If the environment is damp at the installation time due to chemical reactions, polyurethane flooring becomes foam and has an unsightly appearance.

Also, observing the mixing ratio in polyurethane flooring is much more sensitive than other types of resin flooring, such as epoxy flooring. If the exact mixing ratio is not followed, serious problems will occur, which will involve high costs.

Sports polyurethane flooring is self-leveling, and in case of a proper substructure of the flooring, regardless of how it is poured on the floor, it will level itself on the ground and create a smooth, beautiful, and integrated surface.

also read:

installation of epoxy flooring

Steps of polyurethane flooring installation

The general steps of installation of polyurethane sports flooring include substructure and preparation of the substrate, applying primer, middle layer, and polyurethane coating, which are further explained below:

Substructure: cleaning any dirt, smoothing the floor, filling joints and cracks, and measuring the floor’s moisture content. Sometimes it is necessary to spread a layer of rubber mortar, which is a combination of rubber granules mixed with resin. Rubber mortar makes the flooring thickness and flexibility much higher and, at the same time, increases the cost of the sports flooring.

After the substructure, it is time to apply the primer. Primer for proper connection of polyurethane coating to the floor substrate should be applied without any solvent and evenly on the floor.

After applying the primer, the middle layer should be applied with a Flat or comb scraper on the surface. The choice of the type of scraper depends on the amount of material used.

After applying the middle layer, wait until the coating is completely dry. After the floor is parched, possible flooring problems (surface waves, cavities, or cracks) are checked to re-apply the middle layer on the surface if necessary.

The final layer of polyurethane coating, depending on its type, will be applied on the prepared surface using a comb scraper & air catcher roller (self-leveling flooring) or a wool roller (floor coating). Using rollers will give you a rougher surface called orange peel.

Sports Flooring Manufacturer

BASA Polymer sports polyurethane flooring (such as BASADUR® U 303) is a two-component self-leveling polyurethane matrix with high flexibility is very smooth, and is an excellent choice for high wear applications. This product is suitable as a binder with high particle adhesion or final coating for use in places where abrasion resistance is important (such as gyms).