Description

What is Acid-proof flooring? Due to the porous and permeable nature of concrete floors, the use of industrial flooring in places where various chemicals and acids are used (such as chemical fertilizer factories, food, dairy, and beverage factories) is rejected by most regulatory organizations and HSE engineers. has been banned.

If non-absorbent and permeable floor coverings are used, in addition to the destruction of these types of coverings over time, we will witness the spread of chemicals and acids to different places due to a lack of proper cleaning and washing.

Also, according to the industry and its type of activity, if the anti-acid, non-absorbent, integrated, and easy-to-clean flooring is not used, the factory in question may be subject to fines for non-compliance with legal requirements. Therefore, both from the point of view of the stability of the flooring and from the economic point of view, it is better to replace the current flooring with acid-resistant resin flooring as soon as possible.

In this article, the introduction of anti-resin acid industrial flooring (Epoxy Flooring and Acrylate flooring) has been discussed. Stay with us for more information.

In what Places do we need Anti-acid Flooring?

Acid-resistant flooring can be used anywhere where chemical or acid spills may occur.

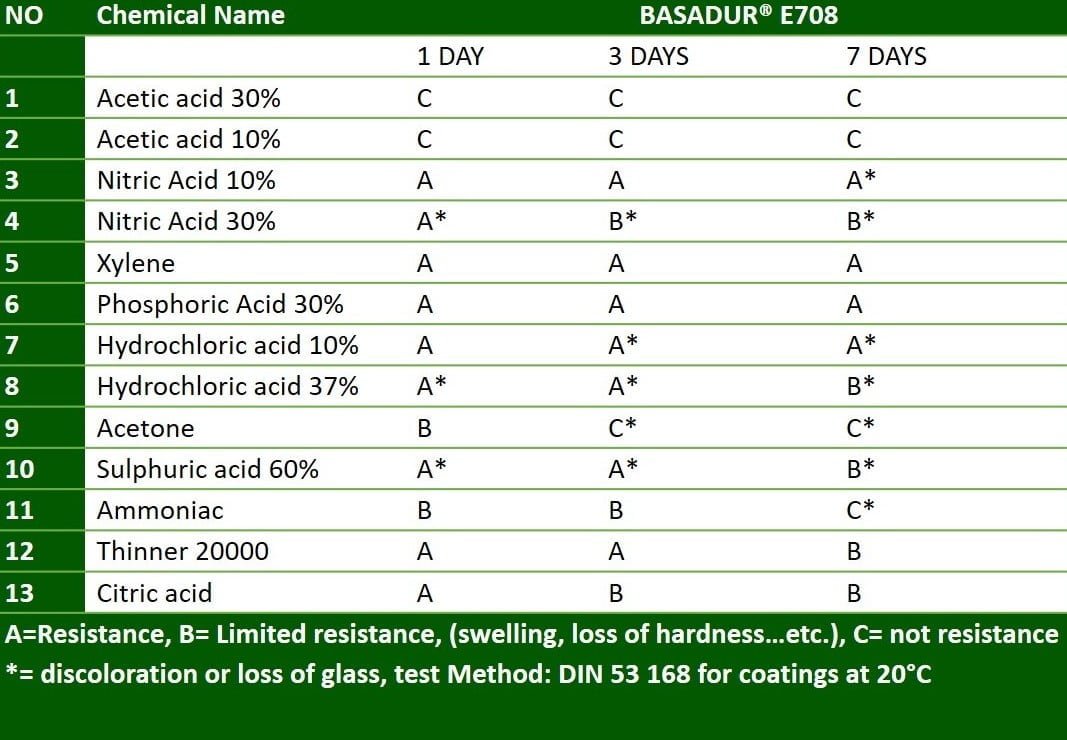

If the acid settles and they mix, the acids may show different behavior. Therefore, before installing and implementing acid-resistant resin flooring, it is better to check the chemical resistance table of chemicals and acids.

Read more:

Areas where acid-resistant resin flooring is most often installed include:

- Battery charging locations

- Chemical storage areas

- Chemical processing factories (types of chemical fertilizers, etc.)

- Food, dairy, and beverage factories and halls

- Tank rooms and…

Types of Anti-acid Resin Flooring

1. Novalac Epoxy: Anti-acid epoxy coating

Every industrial user needs acid-proof flooring according to the type of chemicals, acids, and their activity. One of the most common anti-acid resin coatings is Epoxy Novalac Floor Coating.

Usually, BASADUR® E 708 Epoxy floor coating is used in the final layer of the resin flooring system so that the epoxy floor is resistant to chemicals and acids.

Short usage time, fast curing, low viscosity, and easy application are important features of this anti-acid coating.

Chemical resistance table of BASA Polymer acid-proof epoxy coating

2. Anti-acid Methyl methacrylate final Coating

Another anti-acid coating produced by Basa Polymer expert team is BASADUR® M 501.

This product is produced based on methyl methacrylate (MMA) resin and has a very good resistance to all kinds of acids and chemicals. BASADUR® M 501 is usually used in the final layer of resin flooring systems. The important features of this anti-acid coating are its short usage time, low viscosity, absence of solvent in its formulation, fast curing, and easy installation.

Fortunately, Besapolymer company’s production line is one of the most complete quality resin flooring production lines in the market. Besapolymer specialists with sufficient specialized knowledge and necessary experience in the field of acid-proof flooring design and production will help you to choose the best and highest quality resin flooring according to your use. A high-quality acid-resistant resin floor must withstand long-term exposure to high-concentration chemicals, very low-pH materials, and strongly acidic materials such as 98% sulfuric acid.

For more information and to receive free expert advice regarding acid-proof flooring, the price of acid-proof epoxy flooring, types of acid-proof flooring, etc., you can contact BASA Polymer.

Reviews

There are no reviews yet.