The Adhesion Pull-Off Test of the epoxy coating is performed to determine the adhesion of the flooring to the underlying surface. One of the main tests of epoxy flooring is determining its adhesion, which can be measured in several ways.

If the adhesion of the flooring to the underlying surface is not suitable, there will be a possibility of problems such as creating unevenness in the surface, flaking, separation from the surface, etc. The appropriate level of adhesion of the flooring to the surface is different in different applications and also depends on various factors (preparation of the underlying surface, quality of raw materials, etc.). However, the adhesion strength of epoxy flooring cannot be less than a certain limit determined by the standard.

Adhesion Pull-Off Test

The Adhesion Pull-Off Test, as we mentioned, is used to measure the amount of tensile force necessary to separate the metal disk or dolly attached to the surface of the flooring implemented on concrete.

To perform this test, destructive testing can be used, and to prevent the effect of failure at the project site, the test can be performed on a sample in the laboratory. For this, it is necessary to first apply the flooring on a concrete board sample that is completely smooth, sanded, and cleaned.

The thickness of the concrete and its quality must be by the standard or similar to the concrete used in the installation of epoxy flooring. The dolly surface must also be clean and sanded. Then we coat the surface of the dolly with epoxy glue, carefully stick it to the floor and put it under pressure. After at least one day, we can do the test.

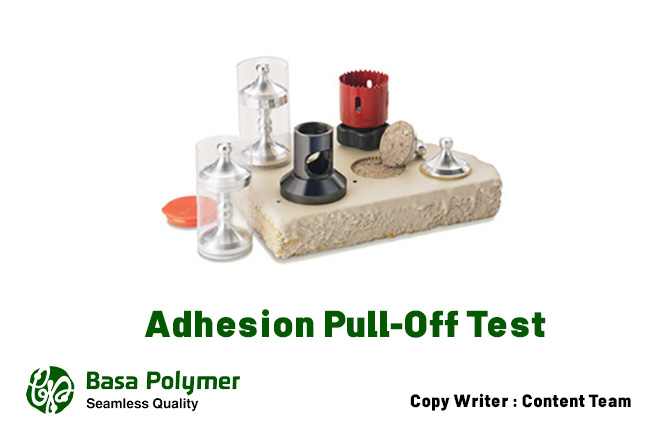

Pull-off adhesion test machine components

• Dolly Dully: It is a metal piece that sticks to the surface of the flooring and is available in diameters of 2 to 5 cm.

• Special glue: The quality of the glue is very important for gluing Dolly, and epoxy glue with proper adhesion is usually used.

• Special jack or digital pull-off test device to apply force.

• Cutter cylinder or circular cutter: to cut around the dolly to increase the accuracy of the test.

Adhesion strength of Epoxy Flooring

Before applying epoxy flooring, choosing the appropriate method of underlying the surface, removing any cracks and seams on the surface, and making sure that the surface is free of any pollution, fat, grease, solvents, etc. are effective in the level of adhesion of the flooring to the surface.

The second step after proper subflooring is to apply an epoxy primer to ensure good adhesion of epoxy flooring to the substructure. The primer penetrates the substrate and creates a unified film, while creating physical contact with the substrate due to its chemical nature similar to epoxy flooring, by creating physical interactions, it strengthens the adhesion of subsequent layers to concrete.

As mentioned, different methods are used to determine the adhesion strength of coatings. Other tests to determine the adhesion strength of coatings are as follows:

1- Test for determination of cross-cut adhesion strength

2- Adhesive strength test in the form of two crossed lines

3- Knife cutting method

The material of the coating substrate, the application of the coating, and its thickness are the most important factors that help to choose the right method for determining the adhesion strength. The important point is that all these methods are destructive tests and can be applied to the final product as a coating.

The most common test to measure the adhesive strength of flooring is the pull-off test. The pull-off test to estimate the strength of concrete was carried out in the mid-1970s at Belfast and Queen’s University, and its reliability was evaluated and led to the construction of the first commercial device named Limpet.

Analysis of adhesion strength test of Epoxy Flooring

We can analyze the following results from the mechanism of dolly breaking from the flooring:

1. If the dolly is separated from the floor surface from the place of glue, that means either the glue is not well stuck between the dolly and the flooring, or there is contamination between the dolly and the flooring;

2. If 50% of the flooring sticks to the dolly and 50% remains on the concrete, there was probably a problem in the implementation of the flooring layers;

3. If the flooring is completely separated from the concrete surface, it means that the adhesion strength of the flooring to the concrete is weak. In this case, the problem was probably in the implementation of the flooring, and it is suggested to review the steps of preparing the concrete surface and applying the primer.

4. The fourth and ideal state is when the dolly is separated from the depth of the concrete. In this case, it can be analyzed that the adhesion strength of the flooring to the concrete is higher than the tensile strength of the concrete and the best possible result will be in the Pull Off adhesion test.