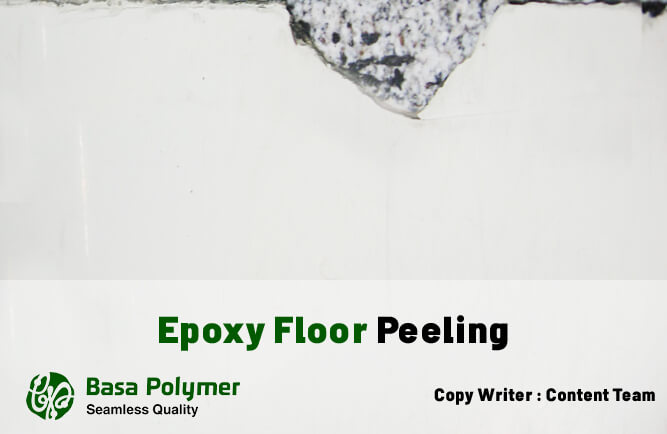

It has happened a lot that customers have complained about the epoxy floor peeling from the substrate, and this problem has caused them dissatisfaction.

This usually happened after a few months of installing the epoxy flooring and parts of the flooring were delaminated, and in extreme cases, it was accompanied by the complete separation of the epoxy flooring from the substrate. In these cases, usually, both the epoxy flooring contractor and the flooring manufacturer blamed the other side. Since both the quality of installation and the quality of epoxy flooring material affect the durability and adhesion of the flooring, it is necessary to know the possible causes of epoxy floor peeling.

In this article, the reasons for the Epoxy Flooring delamination or peeling have been investigated.

What are the reasons for the Epoxy Floor Peeling?

1- Lack of proper surface preparation of epoxy floor substrate:

As you know, epoxy flooring can be used on all kinds of surfaces, including concrete, stone, ceramic, and mosaic. However, depending on the type of substrate surface, the conditions and stages of the surface preparation for the installation of epoxy flooring would differ.

General conditions for epoxy flooring

Any type of dirt, grease, dust, loose spots, and even the presence of moisture can weaken the adhesion of the flooring. The proper substrate of epoxy flooring should be free of any fat and oil. The presence of oil and pollution has a direct effect on the adhesive strength of epoxy flooring and must be completely removed from the substrate during the floor installation stage or removed from the substrate by screeding.

Another important factor that has a direct effect on the adhesive strength of epoxy flooring is the presence of moisture in the substrate (such as new concreting, water leakage under the flooring, or the presence of negative pressure in the negative floors of the building).

The presence of moisture in the foundation leads to the blistering of the epoxy floor. Localized floor peeling or epoxy flooring delamination covering will occur in widespread areas.

Also read:

How does moisture-proof epoxy primer protect epoxy flooring from blistering?

Below are the methods of measuring moisture before applying epoxy flooring

Special conditions for standard epoxy flooring substrate

If the underlying concrete is not thick enough or the mortar used is highly alkaline, all will affect the adhesive strength of the flooring in the future. Alkaline compounds of concrete are corrosive and weaken the effect of primer on the surface of the concrete and lead to the separation of the epoxy flooring from the concrete.

The glazing of ceramics and the degree of permeability of stones as a flooring foundation are other points that must be taken into account when installing epoxy flooring. It is suggested that in the stage of preparing the surface for the installation of epoxy flooring, remove the ceramic glaze and scratch the surface of the stone through the flooring to increase the mechanical contact between the flooring and the substrate and maximize the adhesive strength of the epoxy flooring.

In this way, it is possible to prevent the local epoxy flooring delamination to a significant extent.

also Read:

Installing Epoxy Flooring on Ceramic

2- Choosing a primer regardless of the condition of the substrate:

The role of the primer during the installation of epoxy flooring is to maximize the adhesion of the flooring to the substrate, along with sealing the substrate and closing its pores.

Epoxy primers are offered in different types of water-based, solvent-based, solvent-free, or 100% solid. The depth of penetration of epoxy primer into the substrate, the percentage of volatile organic substances, the primer curing system, and the ability of the primer to withstand negative pressure and water vapor caused by the presence of moisture in the substrate are very important in the adhesion of epoxy flooring to the floor.

In other words, it is better to choose the right primer based on the condition of the epoxy flooring substrate and in consultation with the manufacturer to ensure maximum adhesion to the flooring substrate.

Download the technical information sheet of BasaPolymer moisture-resistant epoxy primer

3- Not paying attention to the service condition when choosing the type of epoxy flooring:

Another key point is the effect of usage conditions on the adhesive strength of the flooring. For example, in places where the floor is washed daily with hot water, due to the thermal shock applied to the epoxy flooring, if there is a difference in the thermal expansion of the flooring on the one hand and the substrate, on the other hand, there will be a possibility of breaking and separating the flooring from the floor. Also, in applications where there is a possibility of heavy objects falling on the flooring (such as warehouses), the thickness and type of epoxy resin used should be selected in such a way that it can dissipate the energy of the impact and prevent the destruction of the substrate and ultimately the separation of the flooring.

In general, it can be concluded that a combination of factors related to the type of epoxy flooring material and its installation method affects the final quality of epoxy flooring and its possible subsequent problems. As a result, proper knowledge of the materials and effective communication between the epoxy flooring manufacturer and the flooring installation contractor is very important in preventing problems such as the separation of the epoxy flooring from the substrate.