Anti-slip flooring: Every year, slipping and falling of people or equipment in different work environments causes a lot of damage to employers, and in addition to the resulting economic losses, sometimes irreparable loss of life is suffered by the injured person or the company. Therefore, establishing security and checking the safety of the workplace is one of the most important instructions that must be paid attention to, and safety, health, and environment (HSE) engineers must check these instructions and evaluate the performance of employers in establishing safety.

One of the main and most important parts that must be considered for its safety is the floor and its related issues (cleaning and repair). Floors of workplaces are constantly exposed to all types of traffic and pollution according to the type of use. For example, power plants factories, and environments that have 24-hour work shifts are exposed to the movement of personnel, heavy machinery (pallet jacks and forklifts), and various types of pollution (types of oils and pathogenic microorganisms) during the day and night. In this way, the floor system of these environments must be carefully selected so that it does not suffer losses both from the point of view of safety and the economy of the employer’s company.

Anti-slip Flooring

Anti-slip or slip-resistant epoxy floors are floors that reduce the possibility of people or objects slipping by having small unevenness on their surface and creating positive traction. Some industries should pay attention to the slip resistance of the flooring when choosing floor coverings.

For example, restaurants, parking lots, food and beverage processing plants, pulp and paper mills, and many other manufacturing plants must have slip-resistant flooring systems. In places like food and beverage processing plants where there is a lot of water, liquids, and other greasy substances on the floor, aggressive industrial anti-slip flooring is necessary for the safety of the workers.

On the other hand, in environments where the ability to clean and disinfect the floor is more important than the non-slip feature of the flooring (such as hospitals, health production halls, and pharmacies), the flooring with moderate to low slip resistance (non-aggressive) is chosen. The more aggressive the slip resistance of the floor, the more difficult it will be to clean.

In aggressive anti-slip flooring, the additive that is added or sprayed onto the flooring is larger and more angular, making it more difficult to clean.

Types of non-slip Epoxy Flooring

2. Non-aggressive anti-slip flooring (moderate resistance to slip) If cleaning and disinfection of the floor are of particular importance, aggressive anti-slip flooring systems are usually not used.

To increase the slip resistance of the epoxy floor, the best, most effective, and easiest way is to apply the orange peel. do, fine unevenness is created on the final surface, which in addition to increasing the floor’s resistance to slip, these types of floors are easier to clean and wash than aggressive anti-slip floors.

Note, sometimes the final surface of the epoxy floor becomes orange peel for various reasons, which is not desirable for the employer. Click to read more about Orange Peel on the Floor.

Pendulum test The quality of non-slip flooring

If, according to the use of the floor, the resin flooring chosen for the environment is non-slip, it is necessary to carry out relevant quality control tests by the resin flooring manufacturers before sending the product to the customer.

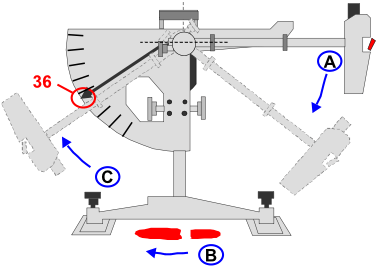

One of the quality control tests performed for anti-slip flooring is the PENDULUM TEST.

In this test, the height of the pendulum is set so that it passes tangentially through the sample after being released. The greater the slip resistance of the manufactured floor sample, the harder the pendulum passes the sample and the less it rises. The figure below shows the steps of the pendulum movement in the resin flooring quality control test.

According to the information obtained from the pendulum test performed on wet non-slip resin flooring, the flooring can be divided into the following three categories:

• Low slip risk surfaces

• Levels with moderate slip risk

• Surfaces with high slip risk

In this way, by checking the amount of traffic and the type of floor in terms of the risk of slipping and performing the pendulum quality control test, it is possible to propose a suitable anti-slip flooring system to consumers and executives.